Wire rope lubricators and wire cleaners as well as other modern tools are essential in the complex world of cable maintenance. Longevity and precision are essential. These devices are innovative and are crucial in ensuring smooth operation and longer life of cables from various industries. This article explores the importance of wire rope cleaners and oil lubricators in maintaining cables. We also examine their benefits and functions.

Understanding how wire rope lubricants work

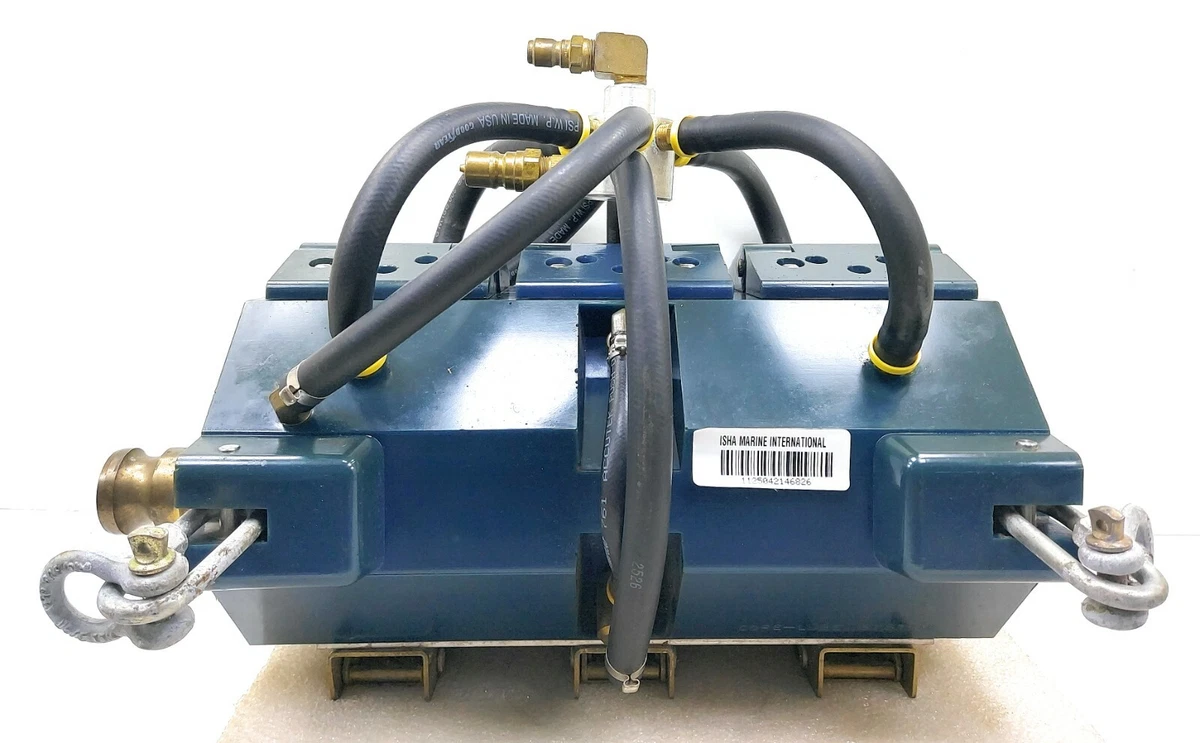

Wire Rope Lubricators are specialized devices that are designed to grease wire ropes in a logical way. This process is vital for preventing rust, reducing friction, and enhancing overall endurance. The lubricator will ensure that the lubricating substance is evenly distributed throughout the length of the rope of wire, ensuring an extensive protection from wear and tear.

What’s the purpose of wire cleaners in the maintenance of cables?

Additionally, wire cleaners also referred to cable cleaners, are instrumental in keeping the cleanliness of cables. They are made to eliminate the buildup of fluids, contaminants and debris that may build up on the cables during various processes. When working in harsh conditions it is essential to use wire cleaning products is vital to ensure maximum performance.

Optimizing Cable Lifespan:

Combining wire cleaners and the lubrication of wire rope can prolong the length of a cable. Through the use of wire rope cleaning to eliminate contaminants, and applying Lubrication, cables are protected from harmful effects such as friction, corrosion, or other external elements. This helps preserve the integrity of the cable and leads into increased efficiency and reduced maintenance costs.

Efficiency in the application

Wire rope oilers are created to be user-friendly and provide effectiveness when used. They are versatile and can be utilized for various wire rope sizes and types. The systematic and automated application of lubrication guarantees consistency that eliminates the danger of uneven coverage that manual methods could cause.

Adaptability to Challenging Environments

Wire rope lubricators and wire cleaners are crucial in industries where cables have to endure harsh conditions, such as those found in construction, drilling or maritime operations. They have been developed to be able to withstand the harshest conditions. They’re therefore highly reliable equipment for maintenance of cables.

Maintenance solutions that are cost-effective:

A proactive approach to maintenance of your cables, involving the use of grease and cleaners for wire rope is a much more affordable option in the long term. The initial investment in these equipments is minimal compared to the future costs, such as repairs and replacements because of poor maintenance. Know more at Wire Cleaner

Conclusion:

Lubricators for wire ropes, as well as cleaners of wires, are the guardians of cable integrity. They guarantee the highest quality, longevity and performance in a variety of industries. Removal of contaminants as well as the application of lubricants contributes to the longevity and preservation of cables. This reduces maintenance and enhances the efficiency of operations. In a field that depends on cables to conduct vital tasks, implementing advanced tools for maintaining cables such as wire rope lubricators or cleaners is not only an excellent choice, but is also essential.